Sponsored

RFID tracking of work, 360 cameras and complex video equipment are among the promising technological inventions for the advertising structure industry.

David Barista, editorial director

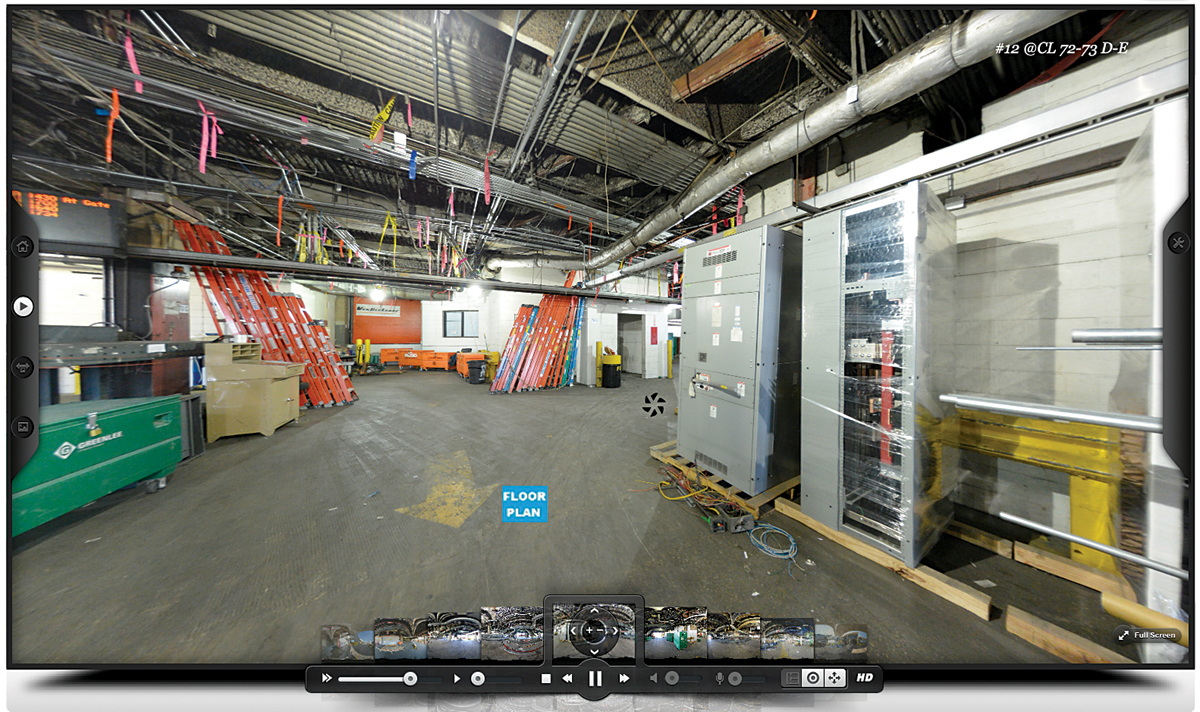

The use through Manhattan Construction of 360 cameras in the DFW International Airport Modernization and Improvement Project has particularly reduced the need for customer/equipment visits to the large site and has advanced the coordination efforts of the existing site. Team members access photos from a virtual map of the structure site. Users can take a virtual tour of the site by scrolling through the series of photographs. Courtesy of Manhattan Construction

Drones, GoPro, RFID, Oculus Rift, augmented reality, 360 cameras, 3-d laser scanners, GIS systems. There is no shortage of technological devices that are ripe to be followed in ad structure projects. Making those generation teams even more exciting for building corporations is the low access barrier (e.g., professional-level drones charge $650) and greater integration with existing workflows and systems.

“It’s been incredibly difficult to check to master all the new innovations,” says James Barrett, vice president and chief innovation officer at Turner Construction. “It’s easy to get carried away by the freshness of those teams, but I feel like some of them are just a solution to a problem.” Turner adopts a slow technique for adopting technology and opts for teams that offer the highest favorable cost-benefit ratio.

In 2013, Suffolk Construction formed a 12-person study and progression team to track emerging technologies. The group, led by Jason Seaburg, senior assignment manager, has a formal procedure for verifying new devices, adding fortnightly calls to the convention, and verifying schedules.

“We paint in an industry that honestly has been in technology for a decade,” Seaburg says. “We want to foster a culture and mindset where it is appropriate to check in beta all new technologies that are coming to market and where it is appropriate to fail. If a specific tool doesn’t work, it’s okay, we’re going to move on to the next thing.”

To find out what technologies they paint for marketers and which emerging programs are promising, BD-C contacted several giant marketers. Here’s what they had to offer:

Manhattan Construction has noticed huge benefits from 360 cameras. Mark Penny of Manhattan, executive vice president of the company’s Dallas office, says the generation has componentatically reduced the need for customer/equipment site visits as a component of the DFW International Airport Improvement and Modernization Project for several years. It also helped the team make sense of existing situations (there are very few drawings as they were built) and document the progress of the construction.

Every two weeks, during on-site scheduled hikes, the task manager uses a Nikon D7100, equipped with a fisheye lens for panoramic shots, to take 4 pictures of dozens of predetermined locations on the site. Photos of each location are assembled using THE PTGui software (www.ptgui.com) and connected to a traditional virtual map of the assignment through Real Tour Vision (www.realexcursionvision.com), allowing any team member to take a virtual high-definition tour of the facility.

“Let’s say a shock to the ducts,” Penny says. “We can see the last photo of this area, scroll and zoom in on that specific location, and collaborate with designers and the consumer, practically, to solve it.”

Technological devices such as drones, GoPros and tablets make it easy to capture video in the field. The challenge for contractors is what to do with the data: how to archive the video for long use or link it to the construction data workflow.

Suffolk and Turner are working with software developers to create traditional teams to help them take their video data. Suffolk plans a YouTube-style online page that will allow your staff to temporarily download and retrieve assignment videos. The latest feature: a complex search feature that will take your audience to a quick point in a video based on keyword input. “Possibly it would be a three-hour assignment video, however, you should watch the basic installation after 12 minutes,” Seaburg explains. “This tool will take you to that precise place.”

Turner is working with software engineers at the University of Illinois at Urbana-Champaign to expand an automated security control program that will analyze video streams to identify personnel using protective equipment, such as helmets, vests, and goggles. “Our purpose has been to leverage the technologies available seamlessly, such as videos and photos, combined with complex analysis, to solve problems,” Barrett says.

No technological innovation has a greater effect on structure projects than prefabrication, Barrett says. Construction crews are experiencing significant gains in the workforce by making plans and efficiency, and are looking for new tactics to move “great thinking” offsite and in a factory-like environment. Prefabricated external walls, unarmed curtain walls, multisectoral shelves, bathroom compartments, prefabricated head walls and appliance skates are now common in primary projects. Emerging programs come with prefabricated foundations and interior partitions.

“The smartest is not a singles arrangement, but a network of structures where contractors put parts into a controlled and blank environment and then deliver them only when needed,” Barrett says.

Business marketing specialists are adapting more sophisticatedly, Barrett says. Quotes to Quakertown, Pennsylvania-based Klover Contracting, which recently introduced a cold-roll-forming BIM machine workflow for manufacturing low-thickness steel frame parts for a variety of programs: internal partitions, company ceilings and flooring, wall mount panels, to call some. Based on the approximate BIM style of a given project, the Klover team can create a detailed structural design that incorporates door/window openings, structural requirements, duct openings, and panel failures. This record is then sent to the company’s cold forming machines, which “print” the component to express the expressions.

To expedite the Brigham construction inspection procedure of 620,000 square feet and 11 floors for the assignment of the Future at Brigham and Women’s Hospital in Boston, Suffolk Construction implemented a QR code-based BIM cash workflow. Team members can temporarily call documents for a given area and provide real-time feedback by scanning a QR code tag pasted into the nearest door frame. Courtesy of Suffolk Construction

Suffolk implements Autodesk’s BIM 360 Glue (BIM/VDC cloud-based coordination) and Autodesk 360 Field (mobile mapping management) for the enterprise. One of the most useful applications, Seaburg says, is the quality control inspection used by the BIM 360 Field app on iPad, combined with QR codes on the site.

In the company’s $280 million Brigham Building for the Future project, 620,000 square feet, recently under structure in Boston, the team placed QR codes on the door frames of the resort area. During paint list inspections (and in all likelihood checkmark list inspections), team members can open the 360 Field app and scan the QR code of a given room for a detailed, real-time list of paints to be performed and the issues to be resolved. Directed.

“From there, we can replace the status, upload comments, dispute it, mark it as finished, and even upload an image,” says Tom Reid, Suffolk’s deputy director of assignments. “This leads us to list paintings in near real time.”

Turner has been tracking RFID for several years and has implemented RFID responses intermittently, with moderate success, Barrett says.

“We’re looking for easily accessible fruits, like tracking workers when they enter and leave the site, and to see if they’re up to date with their certifications,” he says. With newer solutions, such as Trimble’s CrewSight system, Barrett believes RFID is in a prime position.

“Costs are down and it’s becoming less difficult to implement,” he says. “We’re looking to make it popular for projects.”

BIM exchange and knowledge are at the heart of the concept that BIM will lead to a more efficient and environmentally friendly Array.

Umbra worker Elina Nygord uses a pill to see a BIM style on the site before the structure begins. Although this can be done in virtual reality, augmented truth allows you to explore the style in the genuine environment where the finished structure will exist. AR provides architects and clients with the ultimate genuine solution imaginable for a non-specific structure. Courtesy of Umbra

Could a new generation simplify the transition from BIM models to augmented truth pushing AEC to move to Array?

In the most sensitive list of situations demanding for Sandia’s commission, the walls of the structure were under structureArray ..

In the most sensitive list of situations demanding for Sandia’s commission, the walls of the structure were under structureArray ..

Courtesy of Perkins – WIll

According to a report through McKinsey and Company, only the Tourism and Professional Facilities Array sectors.

The Perkins-Will I/O team organizes a planning query for a smart assignment delivery application. The company uses the device to inform teams and processes to be informed about existing and subsequent assignments. Courtesy of Perkins and Will. Courtesy of Perkins and Will.

Machine learning represents a new frontier in the AEC industry that will allow designers to create eArray buildings.

AI professionals most often see very obvious benefits in disorders that have a direct effect on the substance matrix.

Many schools use predictive analytics to reduce atyeration rates for freshmen.

Test a 3D rendering created and modified in real time with Enscape’s real-time rendering software. Mr. Enscape.

With new real-time rendering tools, the mapping can design and render on the fly, for a collaArray.

Plumbing and existing appliances on the roof of the reactor tank prior to renovation.

By integrating creativity and ingenuity with practicality, Moody’s team was able to cope with theArray..

Tennessee State Museum in Nashville

SEE ALL THE BLOGS

Photo: Scott Webb Pexels

All photographs courtesy of B – H Architects

A network in Clark Nexsen’s renovations at Edens Quad Residence Hall at Duke University.

Arup and Suffolk Construction are part of the structure team of northeastern University’s Scientific and Interdisciplinary Technical Complex, which is currently underway. A new pedestrian bridge spanning five subway and rail lines is a key link to the campus. Photo: Evan Patten

Privacy Policy Cookie Policy Terms and Conditions